By Dick Fraser

A box of unusual looking Remington .22 Long Rifle cartridges showed up in a gun shop in Fairfield, CT, just southwest of Bridgeport where it was made. Loaded into conventional copper “U” headstamped cases were these cylindrical lead bullets with a large nose cavity, half filled with dried lubricant. The company name on the box, “Remington

Arms-Union Metallic Cartridge Company” combined with the red ball “Remington UMC”logo indicated mid-teens production. Indeed, decoding the date stamp “G21EFZ” revealed that it was packaged on October 21, 1915. Also rubber-stamped on the top and bottom labels were the letters “GULLY”.

The Remington-UMC catalogs from that time period revealed no acknowledgment of such a loading. Neither Barber’s nor Suydam’s book on rimfires addressed it. I next checked my IAA 50-year Index, but the Gully citations proved to not be relevant. I then turned to my set of Remington UMC ammo related patents which had been kindly reproduced for me by the late Jim Sones….8 BINGO!

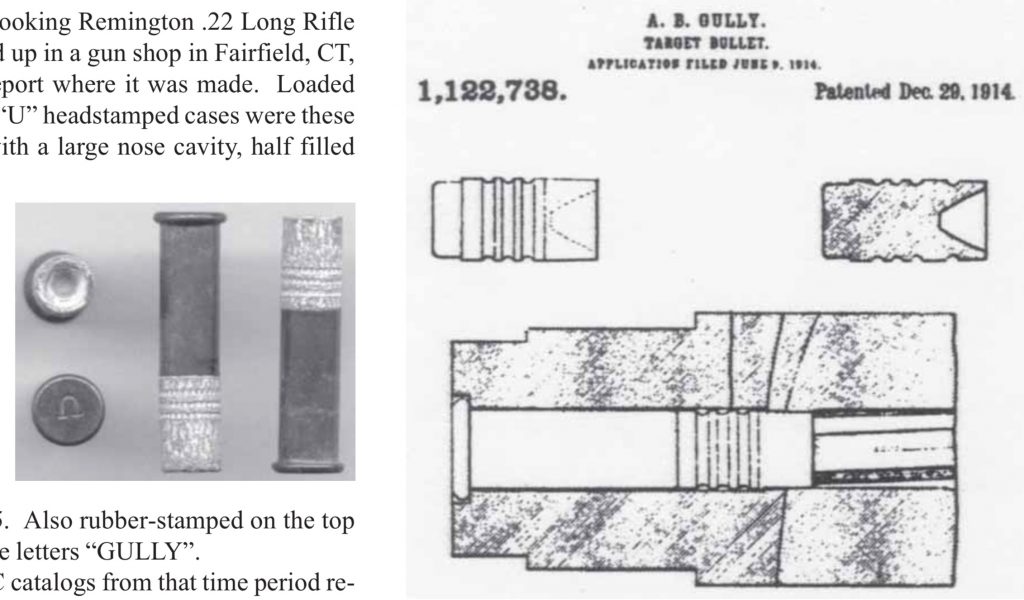

On December 29, 1914 US patent number 1,122,738, “TARGET-BULLET”, was issued to Albert B. Gully of Bridgeport, Connecticut, assignor to Union Metallic Cartridge Company. Quoting from the patent, its object was for a “non-jacketed bullet especially adapted for short range target shooting…which, owing to special details of construction…will produce better targets than has been possible with any bullet heretofore produced, will not tear the target but will cut a round hole therein, will be self-centering in the bore of a gun barrel should it happen to be loose in the cartridge shell and will effectively clean the grooves of the bore and keep them clean.”

The bullet “tip tapers slightly…is provided with a central recess or cavity having an inclined wall…is flat across its forward end…the diameter at the forward end corresponds sub- stantially with the diameter of the gun barrel…”. “Pressure must be applied to the rear end of the cartridge to force the tip of the bullet into the bore…to cause the lands of the bore to form corresponding grooves in the bullet.”

“When the bullet is fired, the effect of the resistance of the air owing to the recess in the tip is to expand the tip outward so that still deeper grooves are formed in the bullet.” This supposedly centered the bullet and scraped the grooves of the barrel clean. Also, “My novel bullet does not tear a paper target but cuts or drills a hole in it of appreciably

greater diameter than the caliber…(which can often) cut sharply two rings of a standard target” resulting in higher scores.

Selections from the patent illustration shows a round almost identical to those in the specially marked box. I would speculate that a small lot of the Gully loads were produced for trial, perhaps given to local shooters to try out, and this is a box that somehow survived to the present.

Another Remington mystery solved!